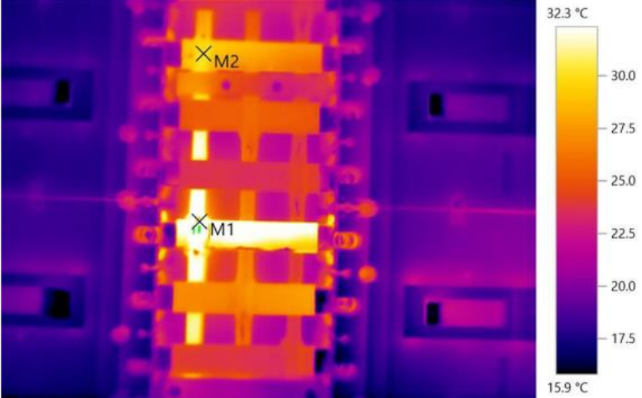

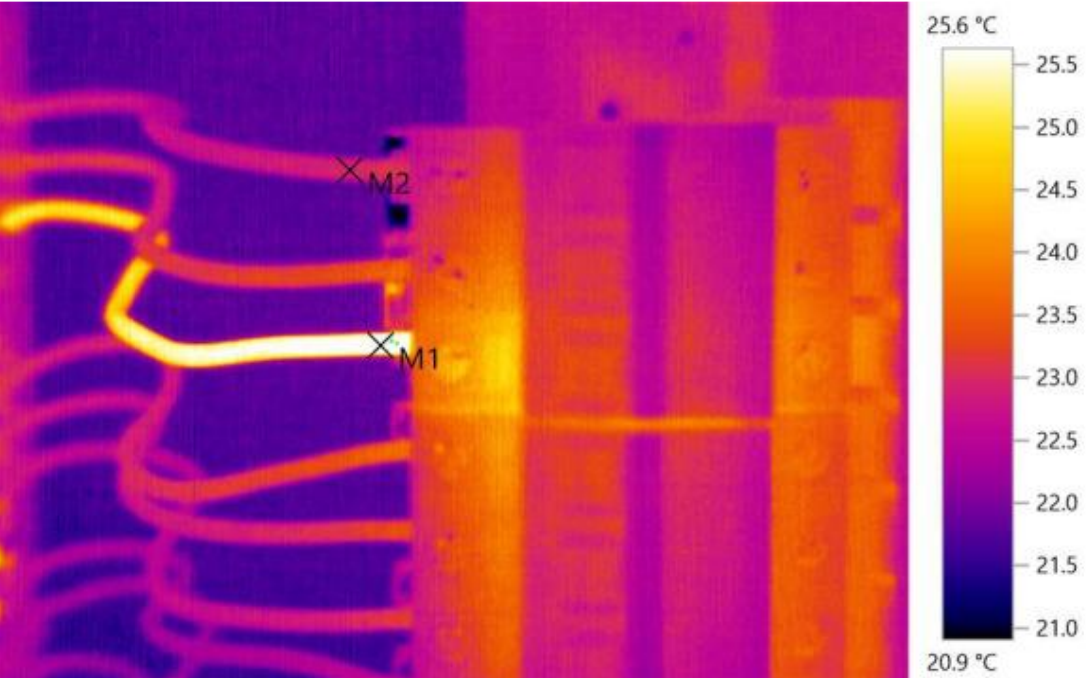

Thermographic surveys, also known as thermal imaging surveys, utilize infrared technology to detect temperature variations on the surface of structures, equipment, or systems. This non-invasive method identifies thermal anomalies that can indicate underlying issues such as electrical faults, insulation deficiencies, moisture ingress, or mechanical failures. By capturing and analyzing infrared radiation emitted by objects, thermographic surveys create detailed thermal images, or thermograms, which highlight areas of concern through color-coded temperature maps.

These surveys are particularly valuable in preventive maintenance, energy audits, building diagnostics, and quality control. For instance, in electrical systems, thermographic surveys can pinpoint overheating components, preventing potential failures and fire hazards. In building inspections, they can reveal heat loss areas, enabling improved insulation and energy efficiency. Additionally, they are used in mechanical systems to detect bearing failures or misalignments before they lead to significant damage.

Thermographic surveys offer several advantages: they are quick, non-destructive, and can be performed without disrupting normal operations. They provide a clear visual representation of temperature differences, facilitating early detection and corrective action. By proactively identifying and addressing issues, thermographic surveys help enhance safety, efficiency, and longevity of various systems and structures.